7. Tired of Screwing With This Sheet... Metal

Back | Top |

Next

Sent: Tuesday, 20 Aug 2002

Tired of Screwing With This Sheet... Metal.

I suppose I should have sent this out about a month ago--but I've had an interesting life outside

of housebuilding.

Well, the roofing ordeal is done. Sort of.

And it's the hardest thing I have ever done in my life.

If anyone ever offers you the chance to work with 19 1/2 foot by 3 1/4 foot (6m x 1 m) sheet

metal during one of the windiest summers on record, run, do not walk, to the nearest gun store,

buy a gun, and shoot them. If I end up on the jury I promise to find that it was self-defense.

But enough griping.

This is an unusual roof--rather than using shingles I opted for something called ProPanel II, which

is a ribbed sheet metal roof. It's supposed to be a 50 year roof. It sure seemed to take

that long to install it. Since the slope of the roof is 19 1/2 feet long, the strips run from

the peak of the roof down to the edge--except where it doesn't because of valleys or hip ridges.

You have to unroll tar paper horizontally--so you end up unrolling ALL of the tar paper before you

can do anything with the sheet metal. A rather dicey proposition. Then haul the panels

up onto the roof and screw them down.

The strips overlap each other slightly on the edges. If the prevailing wind blows from the west,

then you want to put the very first strip on the east edge of your south (or north) facing roof, then put

the next piece directly west of it, so that the wind can't scoop up the easternmost piece--it's tucked

under the piece to its west. Hopefully that made sense. Trying to figure out how to explain

some of these things in words is probably at least as hard as Dante's task explaining Hell and for

similar reasons (oops, I promised to stop griping).

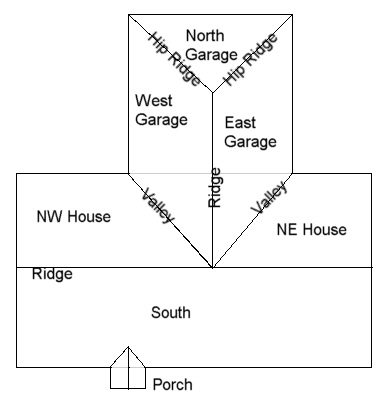

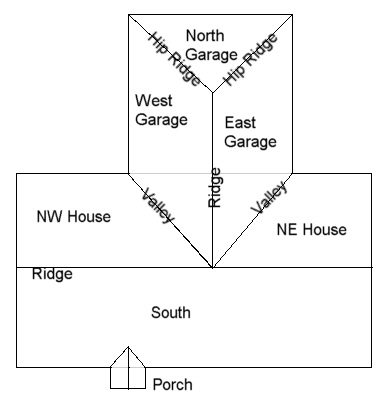

I'll start things off with a diagram:

1) Just so you know what I am talking about, here's a diagram of the roof of the house.

The basic plan was to do the south roof first since very little metal would have to be cut.

It would be a valuable learning experience. Start at the east end and work west. Then

go around to the back of the house, work on the NE roof, east to west again. Just

incidentally I end up cutting a bunch of pieces to go up the valley. I save the parts I cut off.

Then the east part of the garage, South to North since the worst winds are from the north, except

when they decide to blow from the south. I start by cutting pieces--I save the cut-off parts

and use them to go all the way to the northeast corner of the garage.

Then across the north roof of the garage, east to west. I get to use the pieces I cut off for

the NE roof, and then I have to cut more pieces--again saving the cut off parts.

Then the NW roof, West to East. I do it this way because I want to ensure a whole panel on

the west edge of the roof. The bad news is that I have to tuck each panel below the one to

the west since I am doing them in reverse order! I get to use the scrap from the North garage

roof to go up that valley.

Then the last part, the west roof of the garage. Except that it's not really the last part because

the porch needs to be roofed over too....

2) 30 March. I stride boldly off the precipice. What you are looking at is

the SE corner of my plywood box. I've unrolled several rolls of tarpaper part way. I

know the wind is going to be a bit troublesome and so I don't unroll them all the way. The

long strips of plywood nailed to the edge of the roof are so the panels don't slide off before they can be

screwed down. This has been known to happen while people were standing on them, and roof surfing is

still not an Olympic sport so I have no interest in repeating the experience.

3) I took one look at the gigantic pieces of sheet metal and called for help. Finding

out that that help wasn't available, I found that I could wrestle the thing out of the garage,

where it was stored, and walk it around. I then had to set it on the ground, grab a corner,

and climb the ladder. After pulling the thing up far enough that two or three feet were resting

on the anti-roof-surfing guard, I could climb onto the roof, grab the end, and walk backwards up the

roof, trying very, very hard not to tear up the tarpaper in the process.

Then I had to get the screws in. They are supposed to be self tapping.

And the government is supposed to be here to help you.

Of course when a screw won't start you have to apply pressure till it does. The downside

is that you risk having the screw pop out from under the cordless drill, scar up the sheet metal

roof, possibly hit you, and almost invariably fly off the roof. I managed to make a blood

sacrifice to the construction gods with the screw that bit into my thumb on its way to Kansastan.

After dealing with this the first day, someone advised me to simply smack the back of the cordless

drill to get the screws started. When I tried that, the screws went flying. I ultimately

took another drill up there and drilled holes. That worked really well except that having to

kneel on the roof was absolute hell on my knees and feet. (If I didn't kneel, I would more than

likely break the drill bit.) Nonetheless I did a little more than half the roof by either trying

to get the durn things started by pushing, or by drilling.

4) 6 April - Here I am halfway through the next weekend and almost halfway through the south slope of

the roof. If you look at the ground you can see the tracks left by the panels as I pull them up

onto the roof.

Another innovation is the use of more of those strips of plywood to hold down the exposed

tarpaper. What I didn't realize yet was that I hadn't used enough.

Just to the left of this picture is the covered porch, which required some cutting of the

sheet metal to get over the "hump." The next day I got to the porch and cut

off a very small corner to start on my way up it. Incidentally, the valley between the

porch roof and the house roof needs a piece of "valley flashing" to go _under_ the

roof panels. You'll get a better picture of this when I talk about the garage roof.

Unfortunately I don't have a picture of how I left things on Sunday the 7th. It's very

unfortunate.

You see, I had become embroiled in another problem at this time. I had to pause.

I had to put the house on hold. I forgot something though.

If you turn your back on the wind out here it will bite you.

(The "another problem" involved my trying to get the Libertarian Party nomination for

US Senate. Minor detail. As to why it was absolutely necessary that I do this, if

you know why, you know why; and for those of you who don't, I really am not at liberty to say.)

5.) 11 May. What is missing from this picture? The triangle of tarpaper.

The wind literally picked it up and ripped it off at the edge of the metal. There's just a

little bit remaining at the bottom by the porch roof. (And you can see the valley flashing.)

I got to spend an afternoon in a hurricane chasing tarpaper all over my property. I

also got to unscrew the last panel and slip more tarpaper under it.

6.) 29 May--two weekends later I was able to get back to it and finish the south part of the roof.

(I didn't get to be the candidate for Senator. A mixed blessing.)

A neighbor of mine made a suggestion so obvious I just about kicked myself. Take about ten sheets

of the stuff, stack it up, and PRE-DRILL the holes for the screws.

Of course the stuff was already stacked in the garage. Rather than pull the top ten sheets off

(which is what I needed at the time to finish off the south roof), I wedged wood under them and jacked

them up far enough to put more wood under it further down. And so forth. Having lifted the

top ten sheets, I could pre-drill the holes without punching into the sheets below them--which might be

oriented the opposite direction (it matters which end is up because it matters which side is tucked

under the sheet next to it).

*****************

So now it's time to work on the north side of the roof. Remembering my experience from before I decided

to work three-day weekends and get entire sections done. No exposed tar paper for longer than

overnight. Much less risky.

One of the things about plywood boxes is that when it does rain, the inside of the thing is like a

shower. I witnessed that the weekend I finished the south roof. I was able to keep dry

under the part I had done, as the water gushed in everywhere else. It was a one inch (2.5 cm)

rainstorm.

Unfortunately the water really dirtied up the sheets I still had stored in the garage, and there would

be dust and other crud on them until I had the north roof of the garage done. This would make my

life very interesting next weekend.

7.) Morning, Saturday 8 June, after the really scary day. Oh, yeah, that looks

easy, doesn't it?

Well, the day before, I had taken two pieces of sheet metal out of the garage to wash the crud and

caked on dust off of them. I got most of it off. I then started unrolling tar paper.

Unfortunately, I had to unroll a LOT of tarpaper. The reason is that I had to put one strip of

tarpaper over the very peak of the roof, to close the gap at the very top. Since there is a bend

down the center of the strip, it has to be completely unrolled. So I had to unroll a few

yards/meters of it, and tuck it under the metal on the south side of the roof. In order to do that,

the top roll on this side of the roof had to be unrolled that far, the one below it slightly farther,

and so on. So I ended up unrolling a lot more tarpaper than I needed to just to put on the first

sheet of roofing.

Halfway through unrolling all these strips to such a great extent a strong gust of wind came ripping

out of the south. A couple of the unrolled strips of tarpaper were yanked off the roof faster

than you can say "tornado" and as I scrambled to sprawl all over the stripss that hadn't

moved so they would stay put, I SAW THE WIND PICK UP ONE OF THE TWO SHEETS OF ROOFING I HAD WASHED

AND FLING IT COMPLETELY OVER THE OTHER SHEET. If the wind had been blowing out of the north

that day that sheet might have flown up onto the roof and into me.

Then, oddly enough, the wind went almost completely dead.

So perhaps you understand why at the end of the day I threw half a lumberyard worth of wood onto the

roof to hold down the tarpaper. You can see it in the photograph above. And you know

what? The wind was blowing so hard that night I could hear it in town. I had visions of a

repeat of May 11. I got out there and (as you can see in the picture) a couple of the tarpaper

rolls got shoved around, but luckily nothing tore.

As a side note: if you look into the garage you can see my ladder on its side, a bunch of rolls of

tarpaper, and at the very right hand side at the bottom, part of the stack of sheet metal. The

good thing about this part of the job is that I hardly had to move the sheetmetal at all, it was already

close to where it needed to be. And you can see valley flashing between the house and the garage.

8.) 9 June. Northeast house roof done. Inside, the east end of the house is

completely covered and is now dry during a rainstorm-unless, of course, it floods from the

water hitting the rest of the house.

You can see that two of the sheets of roofing are lighter than the others. Those are the two

I tried to wash off. I am not sure which one went flying through the air. On the far right

are nine strips of scrap lumber holding down the valley flashing.

The pieces I cut off to go up into the valley I have stashed inside the house, ready to use on the north

slope of the garage roof.

I think I had to pre-drill 11 sheets for this.

9) The east roof in progress, midday Saturday 16 June. The pieces toward the right

are cut off from the bottoms of the pieces outside of the picture to the left. I am

managing to throw very little metal away. Of course I am still saving the half of the north

roof that I cut off from the NE roof pieces.

10) 21 June--here are the pieces I cut off from doing the NE part of the house roof, stored

in what will eventually be my living room. That grey and black lump at right is a pile of

the tarpaper I had to retrieve from all over my land on May 11.

All I have to do is put these pieces up on the north garage roof and I am halfway done with that.

By the way, cutting these sheets is an ordeal in itself. I tried using tinsnips like someone

suggested. That someone has far more grip strength than I do. I couldn't get the snips

over the ridges. So I got a metal cutting blade for my saw. That of course left all kinds

of burrs on the metal (and chewed up the sawblades like you wouldn't believe), so I used a grinder to

remove the burrs, then I had to paint the cut and wait for the paint to dry before trying to move the

metal. A single cut took over an hour.

INTERLUDE. The north part of the roof is the smallest piece. Before doing the northwest roof

of the house and the west roof of the garage, I had a minor little problem to take care of. Right in

that corner, below the valley, was a five foot deep hole, where the water supply plumbing goes into the

house. It would have to stay there until the trench to the well and cistern was dug.

It made a LOT of sense to do this right now. It would be very difficult to work around this deep

pit and the big pile of dirt next to it.

So it was time to call Tom and have him bring his backhoe, and try to connect the well to the house.

That would take a good portion of the weekend but I was working on the very smallest piece of roof so that

should work well.

11) 22 June. I remember very little of doing the north roof but quite a lot of what happened this

weekend. I took this picture shortly after getting the cistern, so what you see here represents

the work I did on the 21st.

12) Here is the gaping hole in the ground. It's right in the corner between the west

garage and NorthWest house. So here we are about to try to trench and fill. First of

course I had to get the pipe out from under the dirt that had collapsed onto it over the last

winter. So I had to get down into the hole with a shovel the old-fashioned way.

13) Well, it seemed like a good idea at the time. Unfortunately we have had so little rain

this summer that the trench kept collapsing as my friend Tom backhoed. One time it even buried

me up to my knees. So after trenching about 30 feet, we threw in the towel. I called the

inspector and begged to have 30 feet (9m) of what should be a 200 foot (60m) trench inspected.

The inspector did come out, after I had waited on him the entire day, and we were able to fill in most

of this trench--those parts that weren't "self filling" that is.

14) Back to working on the roof, now that I've emptied the sand out of my shoes.

I had to cut the sheets for the west half of the north roof of the garage. But of course

the "scrap" pieces would go onto the northwest roof of the house.

I spent nearly as much time here as I did up on the roof. In the background is the stack

of sheetmetal. It's hard to see but there is a bunch on the floor of the garage, and a bunch

on blocks above it. Those are the sheets I predrilled. I predrilled the rest of the north

roof and the NW house roof at the same time. So the sheets under the block will end up being

used on the West garage roof and are the last sheets I had to deal with.

In the foreground is a sheet flipped over on the unpainted side. The green stripe on the edge

is where I have painted. At the very bottom are my saw and grinder.

15) 14 July--After doing the north roof, I went on a week long vacation. This actually means

two weekends off. I came back and started work on the north west roof of the house.

You can see where we stopped trenching (where the pipe is tangled up).

This was another of those situations where I had to tuck tarpaper under the metal on the other

side of the roof. Although the wind didn't really rip up any tarpaper this time (thanks

to having lots and lots of wood up there to hold it down) it was gusting badly when I was trying

to tuck 12' strips under the south roof sheet metal. One time the wind pulled the paper out

and wrapped it around me, in about 12 milliseconds. Pretty astounding. It was a hard

weekend. This is also the weekend where I had to tuck the sheets under the next sheet

because I was working west-to-east.

16) 21 July. This is a milestone. I've covered the entire roof in tarpaper.

Why take the risk? because the hip ridge has to be tarpapered starting from the bottom and

working up. Any overlaps have to be so that water doesn't get under the paper. So at

this point I had to bite the bullet and do all the tarpaper and hope I had enough lumber up on

the roof to hold it down.

At this point, in theory, the roof is waterproof.

Actually the very next piece of sheet metal nearly blew off the roof once I had it in place.

I had to somehow lie on it and reach for the drill that I had cleverly placed about ten feet away.

The wind was no worse than usual except it was blowing in just the right direction to keep threatening

to cause a disaster.

(This note added 12 December 2002.) That next sheet was also the LAST full sheet to be done. (I had to

trim one corner off but so what?) I picked it up off the garage floor and there were no more sheets

underneath it. I could see part of my floor that was completely inaccessible till then, being under

thousands of pounds of sheet metal. That was a stunning realization. But a pleasant one!

The immense sense of relief--relief that this job was done--when I saw that bare concrete is

something I will remember for a long time.

17) 21 June. And now it's DONE. No more looking like a wart on a pickle to people driving

up the road. No more screwing on the roof.

Well, sort of.

All of the bottom edges of the roof, the bare pine wood, needs to be primed and painted. Then,

special pieces of metal need to be tucked under the metal roof. These provide a drip edge for

rainwater. Then, up the sides of the house, more special "drip eaves" to hold down

the sides of the roof. Then ridgecaps to protect the tarpaper I painstakingly tucked over the

ridge.

And of course the porch is still not done.

So there is more detail work to be done, but the really hellish work with the huge pieces of

sheetmetal is over.

I look back on this with an air of unreality. On the one hand I can't believe I went through

it; another part of my mind has to remind itself that it is over, and that I do NOT face more of

this when I get out to the house this weekend. If you've ever gone through a sustained

stressful period you probably know the feeling (or maybe I am unusual).

.....Anyhow, I took the next two weekends off and went to New York City for a convention. I

came back and discovered that the place that I *thought* had the siding I wanted, didn't; so I had

to order it. Finally this last weekend (17th and 18th) I got to start on the windows and

siding. But that's a story for next time.....

Steve

Back | Top |

Next